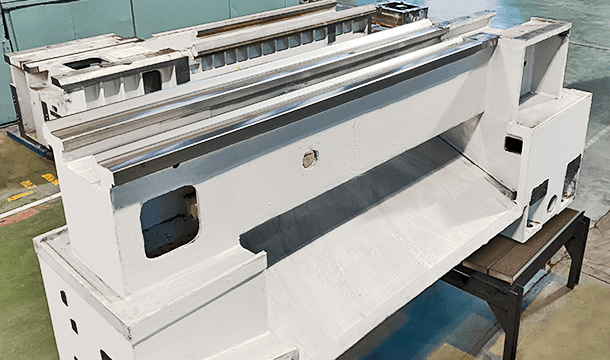

The machine-building factory "Sasta" performs machining processes of its own casting - complex body parts for the metal cutting equipment production.

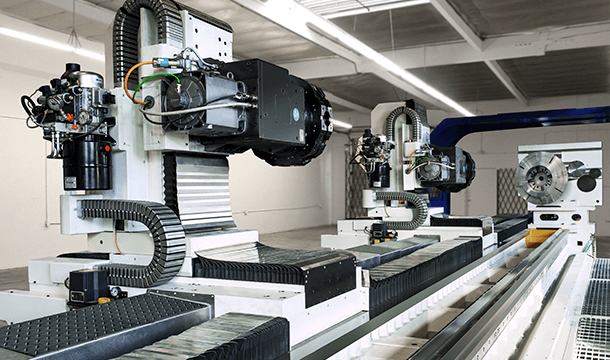

The equipment stock of the factory has more than 200 pieces of equipment, among which there is a unique: